The steel at the core of our barndominium home kit frame system is the same high-grade material used in all our tubular steel buildings for many years. Sourced only from proven, reliable suppliers, it meets stringent requirements for alloy content and characteristics. We require Material Test Sheets with every lot we accept, for quality verification.

Completed frame system

Completed frame system The same frame with a stucco finish

The same frame with a stucco finish

Just a few of the benefits of our metal frame:

- Cost effective when compared to wood-frame construction.

- Fire resistant.

- Easy to put up. No special equipment needed.

- You can get instant pricing on a structure that matches your specifications, and have it shipped to you ready to install.

- No cutting. No waste.

- You never have to mess with complicated calculations, lists, regulations and codes.

- Corrosion and rust resistant.

- Termite proof.

- Use any kind of siding you want – metal panels, wood siding, stucco, etc.

- Made with high-grade steel and designed to withstand the harshest environments. Click to see tech details.

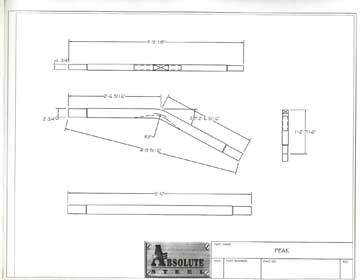

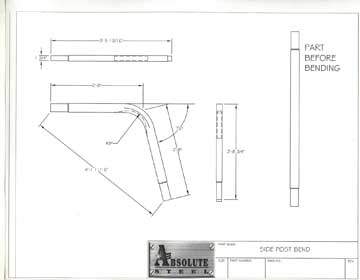

The steel frame systems in all of our garage kits are designed to distribute load stresses evenly, throughout the frame.

Neat, Bundled Delivery to Your Job Site

Easy to install frame system designed for the DIY’er

Other building kits are assembled by attaching purlins and girt to a rigid I-beam. This heavy beam bears almost the entire load stress of the building. That’s why it has to be so big and heavy, requiring a forklift or crane to assemble. Absolute Steel has come up with what is a better, more economical solution: Distribute the building’s weight as evenly as possible, over the entire frame. This has proven completely workable and entirely reliable. It costs far less, is far easier to erect, and requires no cranes or lifts, and there’s no heavyweight foundation to engineer and pour. There are no extra bracing members, and no cross-tie cable-and-turnbuckle system to rig up, just to keep your building upright and square.

A Better Solution

Watch a Building Get Installed

The below video was created and sent to us by a happy customer. Message from the customer who sent it to us: “Attached is my building project. As you can see it is finally finished and turned out great. For all the naysayers I built this pretty much by myself. A 71 year old guy with only some minor help from my wife and a friend once in awhile.“

Alternate Exterior Finish:

If you are out to make your new building match up or blend in with other buildings on your property or have HOA constraints, ask for our Sierra or Alpine style. The framing in these styles are designed to allow you to sheath your garage in almost any type of finish you desire. Whether you want wooden siding, a rustic log cabin look, stucco or stone, bricks, shingles or shakes, the Sierra or Alpine is your best bet.

Exterior and Interior Framing

When you order your barndominium home kit from Absolute Steel, you receive:

- The steel exterior frame ready to be assembled

- Exterior wall panels

- Complete roof including framing and panels

The series below illustrates how our kits work with custom interior framing. Click image for a better view. Interior framing and other buildout is provided by the customer or contractor, and not by Absolute Steel.

Purchasing a Frame Only:

If you’re looking for just a building frame, rather than a full kit including roofing, siding and so on, we’ll be happy to set you up. Just give us a call and fill us in on what you need.

Please call us toll-free at 1-877-833-3237 with any questions or quote needs! We are here to help.

Customer service and pricing available from 8:00 am to 5:00 pm Arizona time Monday – Friday.